VK-KK HISTER SERIES STEAM STERILIZATION TORS

VK-KK Series sterilizers are designed to be used in the Central Sterilization Units of hospitals. They are manufactured in different types, 75,135, 200, 250, 300, 422, 550, 756 and 1000 liters according to their capacities. The latest technology, reliability, easy use and user safety are in design. Sterilization cabinet, cover, steam generator, heating jacket, pipes and connections carrying steam and water are used in AISI 316 T. The sterilization chamber is rectangular prismatic and subjected to electro polishing. Sterilization chamber and cover are guaranteed for 10 years against rusting and deformation. HISTER Series Steam Sterilizers are used for sterilization of all materials that can be sterilized by pressure steam or 316 L, outer walls, main body profiles are made of AISI 304 quality stainless steel and have a 10-year warranty. or double (septic-aseptic), again with flywheel or sliding type cover, according to demand. Steam generator, at least one sterilization water reserve tank and vacuum pump are mounted inside the body. Sterilization chamber has safety valves against excessive pressure. The door does not open until the sterilizer room pressure drops to the ambient pressure and the sterilization process does not start until the sterilizer cover is closed. The sterilizer cabinet, jacket and steam generator are isolated with mineral wool that does not contain asbestos and chloride, which is harmful to humans and the environment. This isolation material is also coated with aluminum plate. The air entering the sterilizer passes through a HEP A filter with 99.99% efficiency, preventing the passage of particles larger than 0.3 microns. There are two external inputs for temperature and pressure for validation purposes in the sterilizers. electric motor and moves vertically or horizontally. The sealing of the doors is ensured by an inflatable silicone gasket. The gasket changes without disassembling any side of the device. There is a safety system on each door (sliding door models) that moves the door in the direction of opening in case of hitting any material. Doors are resistant to high pressures. Door outer surfaces are covered with heat insulation material. It has a lock system that prevents opening when there is pressure in the cabin and before the program ends. In the device, cabin, jacket and generator temperatures are controlled with A class Pt 100s and it is possible to monitor continuously from the screen. Steam jacket, cabin steam feeding, steam generator, vacuuming and drainage of the cabin are done with pneumatic valves. There is a test nozzle in the generator line to measure the steam quality of the device. . The device can perform leak air test and Bowie-Dick test at a time that the user can set. At the end of these tests, the device allows the cover to be opened. At a time that the user will set, the device can automatically switch on and turn off automatically. While there is no operation on the device, the stand-by system is automatically activated at a time determined by the user, and this system can be deactivated by pressing a single button when the operation is desired.

During the Bowie-Dick Test, including all connections, max.120 liters of water and approximately 15 KW electricity are consumed. From the printer that can print documents in a maximum period of 2 minutes, Sterilization pressure, Sterilization time, Sterilization time, Drying time, Sterilization temperature, User name Number of registers, Program name, T start, hour, number of pre vacuum etc.

Information can be printed.The steam generator will be able to produce the steam that the device needs.

selected in capacity. Generator test pressure is 7 bar. the device does not have an external unit and is a whole. Microprocessor unit LCD touch screen Analog manometers are available on the device that show the cell, jacket and generator pressure independent of the microprocessor. Alphanumeric graphic printer can be supplied as thermal or dot matrix. All electrical equipment and mechanical equipment used in the devices are in accordance with the standards. , jacket and generator temperatures are controlled with A class Pt 100s and it is possible to monitor continuously from the screen.

kapasitede seçilir. Jeneratör test basıncı 7 bar dır . cihaz harici bir üniteye sahip değildir ve bir bütündür.Cihaza, dışarıdan hava vs. Gibi bağlantılar yoktur.Mikro prosesör ünitesi LCD dokunmatik ekran Cihaz üzerinde mikroişlemciden bağımsız hücre, ceket ve jeneratör basıncını gösterir analog manometreler mevcuttur.Alfanümerik grafik yazıcı termal veya nokta vuruşlu olarakisteğe göre temin edilebilir .Cihazlarda kullanılan tüm elektriksel donanımlar ve mekanik donanımlar standartlara uygundur.Cihazda kabin, ceket ve jeneratör ısıları A sınıfı Pt 100 ler ile denetlenir ve ekrandan sürekli izlemek mümkündür .

STERILIZATION STAGES

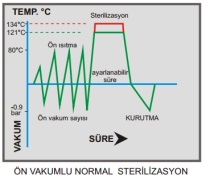

PRE-VACUUM NORMAL STERILIZATION FIGURE: 3

1. FRONT V-BATTERY NORMAL STERILIZATION PROGRAM: In this program, the temperature value is selected by the user as 121 C or 134 C. Before starting sterilization, 2 times preheating and 3 times vacuum process is performed. During preheating, the cabin temperature rises up to 1 15 C. The sterilization time can be adjusted by the user up to 59 minutes. The drying process is carried out by vacuuming up to -0.94 bar in the sterilization cabinet for a time set by the user up to 59 minutes. After the drying process, the sterilization process is completed by equalizing the chamber pressure to the ambient pressure.

2. EXPRESS PROGRAM:

Kurutma islemini de kapsayan acil sterilizasyon islemleri için kullanilan bu programda sterilizasyon sicakligi 134 C olarak kullanici tarafindan seçilir. Sterilizasyon öncesi 2 kez ön isitma ve 2 kez vakum yapilir . Sterilizasyon süresi 5 dakika, kurutma süresi ise 10 dakikadir. T oplam islem süresi ise yaklasik olarak 25 dakikadir. Program, kurutma islemini müteakip basinç esitleme ile son bulur. Sekil 4, ekspres programin kabin içi süre, sicaklik ve basinç grafigin

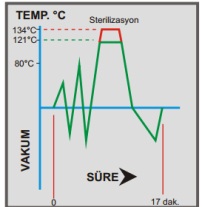

2. EXPRESS PROGRAM:

Kurutma islemini de kapsayan acil sterilizasyon islemleri için kullanilan bu programda sterilizasyon sicakligi 134 C olarak kullanici tarafindan seçilir. Sterilizasyon öncesi 2 kez ön isitma ve 2 kez vakum yapilir . Sterilizasyon süresi 5 dakika, kurutma süresi ise 10 dakikadir. T oplam islem süresi ise yaklasik olarak 25 dakikadir. Program, kurutma islemini müteakip basinç esitleme ile son bulur. Sekil 4, ekspres programin kabin içi süre, sicaklik ve basinç grafigin

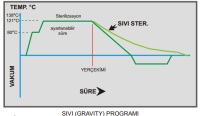

3. LIQUID (GRA VITY) PROGRAM: This program is designed for the sterilization of liquid substances at 121 C temperature without applying vacuum to the sterilization cabinet. After preheating, the sterilization process starts. The sterilization time can be selected by the user up to 59 minutes. Following this process, the cabin pressure is allowed to drop freely with cooling. In Figure 5, the graph of the duration, temperature and pressure in the cabin in liquid sterilization

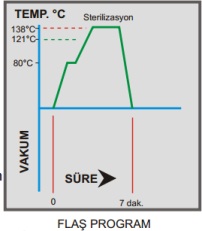

4. FLASH PROGRAM: (For models up to 300 liters)

In this program, which is mainly used for the sterilization of surgical instruments, 2 pre-vacuum

and drying for 5 minutes. Sterilization process at 138 C for 5 minutes

takes place. The total sterilization time is 7 minutes.

4. FLASH PROGRAM: (For models up to 300 liters)

In this program, which is mainly used for the sterilization of surgical instruments, 2 pre-vacuum

and drying for 5 minutes. Sterilization process at 138 C for 5 minutes

takes place. The total sterilization time is 7 minutes.

5. PRION PROGRAM:

This program is similar to the 134 C packed material sterilization program. However, sterilization

Its duration is at least 20 minutes. Thanks to Bowie-Dick and leak test programs, the sterilization quality can be controlled by the user at any time. The user can use this test after entering a four-digit password. The device automatically performs a cabin leak test program at every start up.

STERILIZATION CONTROL SYSTEM:

All stages of sterilization are controlled and monitored on a 7 "touchscreen and 65.000 resolution graphic display. In addition, personnel errors are minimized thanks to the menus designed for industrial purposes to provide the easiest use that does not require long training periods. Sterilization is ensured to be reliable thanks to the auto control system that prevents the user from going beyond the sterilization standards. The user can continuously monitor the general condition of the device while navigating through the program pages. During the program selection, it can easily reach the desired program. The main control system of the microprocessor control has been prepared and validated in accordance with EN 285 - EN 14180 Standards. The following programs are made with microprocessor control.

* Bowie-Dick Test Program,

* Leak Test Program

* Heating Test Program

* 121C- Rubber-Glass Material Program

* 121C Fluid Program

* 134C T ekstil-Surgical Instrument Program

* 134C Gravity Program

* 134C Prion Sterilization program

Microprocess control system ensures complete and error-free operation of the control and control mechanism. When it is not possible to correct possible errors within the system (such as lack of water, etc.), the device is automatically initialized. This situation is notified to the user as a printout and on the touch screen. During operation, all parameters can be monitored both alphanumerically and in real time on the graphical screen.

After the program is started with the relevant program key, the process is carried out automatically without any further intervention. It also has an illuminated and audible warning system.

Sterilizers also have ETHERNET and / or RS 232-485 to connect to a computer or computer network. User-defined programs and programs in power cuts

It has a 10-year battery system to prevent it from being lost. Control panel in double door devices

is on the loading side. The whole control is made from this panel. Located on the clean side

Door opening-closing control is made from the panel only at the end of the process.

Control panel inputs are protected by PASSWORD. Unauthorized intervention is prevented. The device has a calibration program. In this way, temperature and pressure sensors are easily calibrated.

For this purpose, there are two independent entrances on the boiler.

The device has electrical and mechanical equipment and software to prevent danger in case of any error.

REAL-TIME GRAPHIC MONITORING SCREEN REAL-TIME NUMERIC MONITORING SCREEN

* 125C- Rubber Material Program

In this way, the device can observe control and supervision of all other processes.

User, hospital and program names can be entered using the buttons on the screen.

Apart from these programs, there are 10 tests and empty ones that the user can add to the system.

There is also a choice of programs.

The control and control unit is designed for use in steam sterilizer devices.